UK scientists are innovating in the electronics industry by developing PCBs using hemp and other natural fibers to replace harmful materials. The initiative was supported by a government grant and parallel research in Germany and Sweden that focuses on making electronics more sustainable by enhancing recyclability and reducing electronic waste, with potential global environmental benefits.

UK Scientists Aim to Produce PCBs From Hemp Fibers

In the United Kingdom, scientists are taking steps to revolutionize the electronics industry by utilizing hemp fibers and other natural fibers to replace environmentally harmful materials currently used in conventional printed circuit boards (PCBs).

Experts from Jiva Materials in Waterlooville and the University of Portsmouth are working intensively on the development and commercialization of this concept, thanks to a government grant. Similar research is also being conducted in Germany and Sweden, indicating a global interest in the subject.

For more news like this, along with all the latest in legalization, research, and lifestyle, download our free cannabis news app.

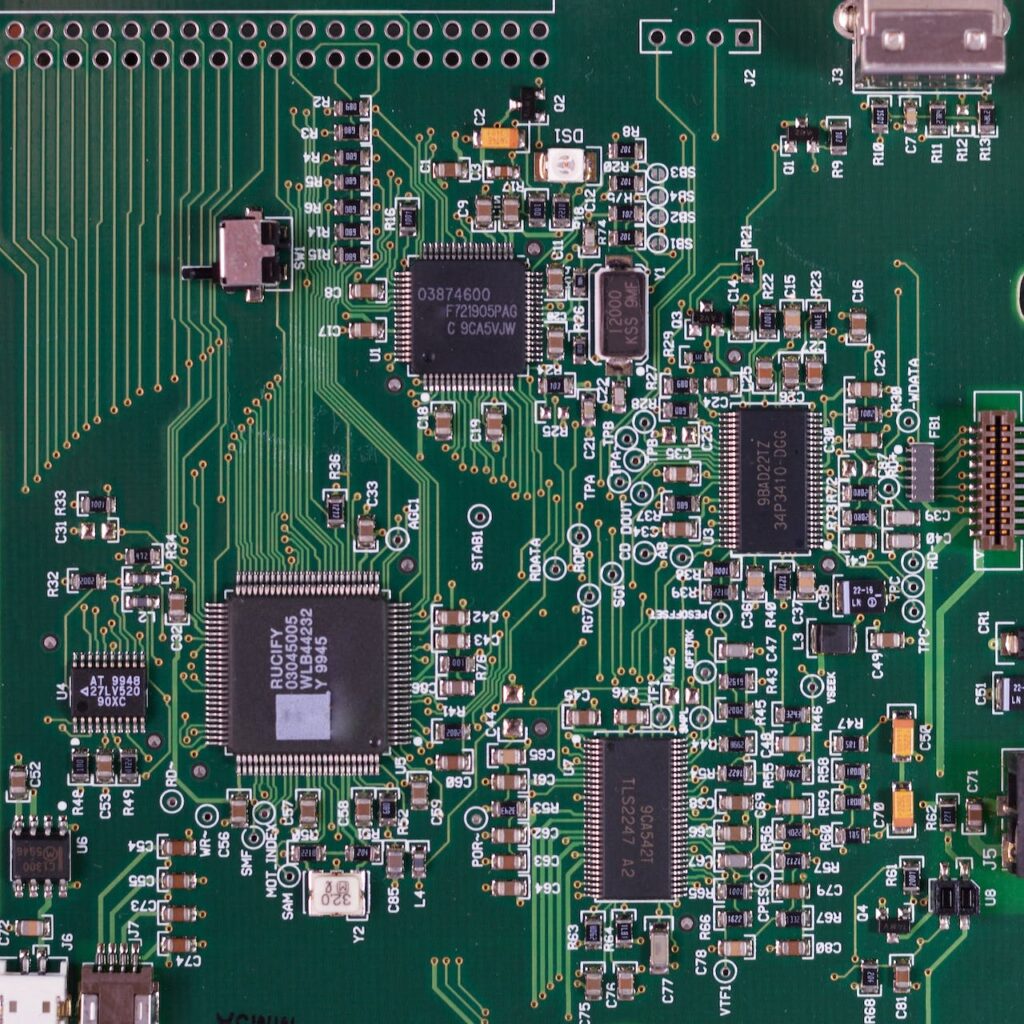

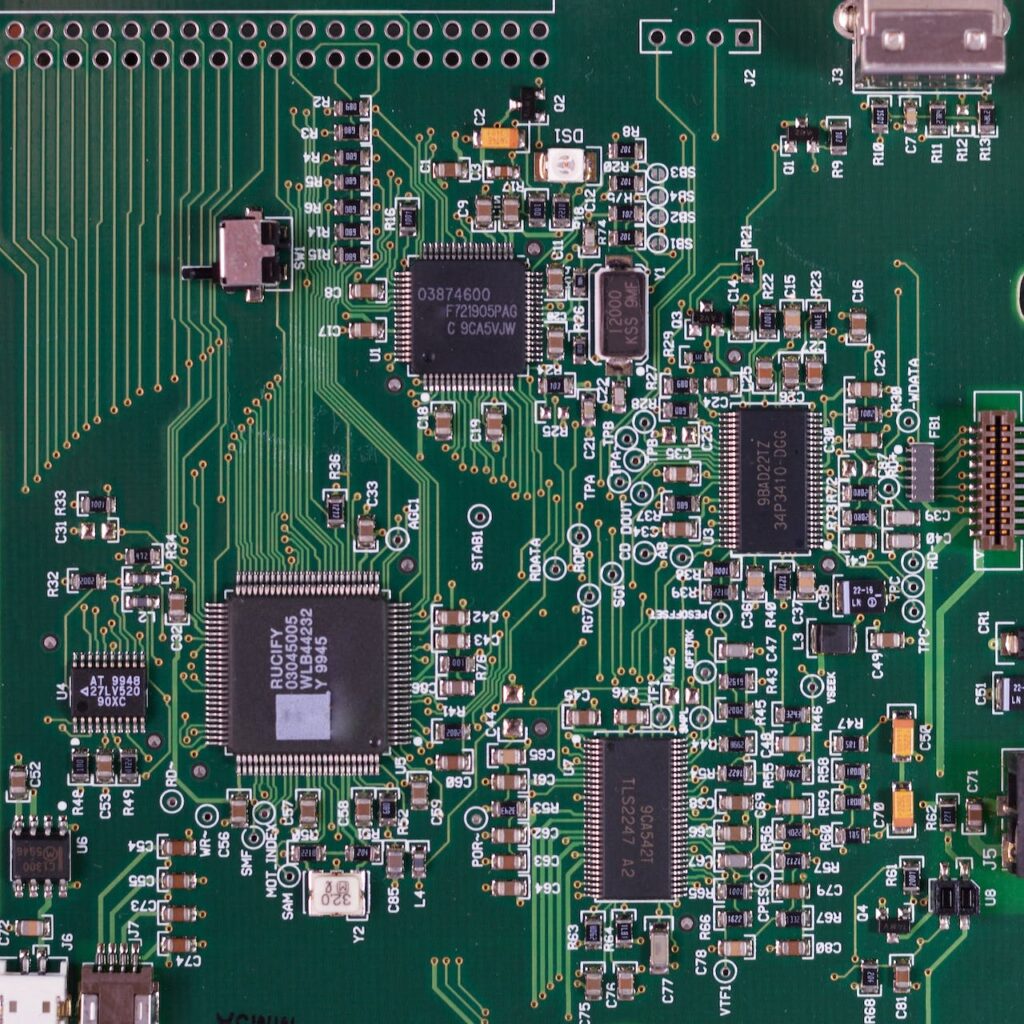

Printed Circuit Boards (PCBs): The Heart of Modern Technology

Printed circuit boards are used in a wide range of devices, from pacemakers to space rockets, serving as the hidden “brains” of modern technology. Traditionally, PCBs have been made using epoxy glass, which has contributed to environmental pollution for over 70 years.

At the end of their lifecycle, less than 50% of electronic waste from these boards is recycled, and the content of valuable metals such as gold, silver, or platinum is too low to make their recovery cost-effective.

The Electronic Waste Problem

Electronics are generating a growing waste problem worldwide. According to Jiva Materials, the average global citizen produces approximately 7.5 kg of electronic waste per year, with PCBs accounting for about 8% of all e-waste.

The alternative developed by Jiva and the APC research group involves impregnating natural fibers with a water-soluble and flame-retardant agent, which facilitates the recovery of electronic components containing valuable materials.

Ecological PCBs Based on Natural Fibers

PCBs based on natural hemp fibers can have a carbon footprint up to 60% lower compared to glass-epoxy technologies and can help reduce the amount of critical minerals ending up in British landfills, which costs about 8 billion pounds annually.

Laminates based on hemp, flax, and jute fibers can be fully compatible with current PCB manufacturing processes, such as acid/base etching, plating, drilling, milling, or curing, as highlighted by researchers.

Innovations and Funding

With a research grant from the “Innovate UK” program, the research team will continue to work on flax-based composites and begin exploring the potential of hemp and jute composites.

The APC research group at the University of Portsmouth, part of the Faculty of Mechanical and Design Engineering, focuses on research into sustainable composite materials and manufacturing methods through industry collaboration.

These initiatives represent a step forward towards more sustainable electronics development, paving the way for reducing the negative environmental impact of this industry. The use of natural hemp fibers, along with flax and jute in PCB production not only reduces the emission of harmful substances but also enhances recycling possibilities, contributing to the solution of the global electronic waste problem.

—

(Featured image by Miguel Á. Padriñán via Pexels)

DISCLAIMER: This article was written by a third-party contributor and does not reflect the opinion of Hemp.im, its management, staff, or its associates. Please review our disclaimer for more information.

This article may include forward-looking statements. These forward-looking statements generally are identified by the words “believe,” “project,” “estimate,” “become,” “plan,” “will,” and similar expressions. These forward-looking statements involve known and unknown risks as well as uncertainties, including those discussed in the following cautionary statements and elsewhere in this article and on this site. Although the company may believe that its expectations are based on reasonable assumptions, the actual results that the company may achieve may differ materially from any forward-looking statements, which reflect the opinions of the management of the company only as of the date hereof. Additionally, please make sure to read these important disclosures.

First published in Fakty Konopne, a third-party contributor translated and adapted the article from the original. In case of discrepancy, the original will prevail.

Although we made reasonable efforts to provide accurate translations, some parts may be incorrect. Hemp.im assumes no responsibility for errors, omissions or ambiguities in the translations provided on this website. Any person or entity relying on translated content does so at their own risk. Hemp.im is not responsible for losses caused by such reliance on the accuracy or reliability of translated information. If you wish to report an error or inaccuracy in the translation, we encourage you to contact us.

Comments are closed for this post.